Well then, where to start

I guess it's only logical to pick up where we left off a couple of days ago.

There's not a whole load of photos of the build over the last couple of days, as well the build itself has been more important

We left things with both engines being out and the old engine ready to move into it's new home

Out with the chains and in it goes

Engine in place it was time to add bits like the poly engine mounts and all manner of new bits.

One of which goes on here

Et voila

That's where we'll leave the engine, for now.

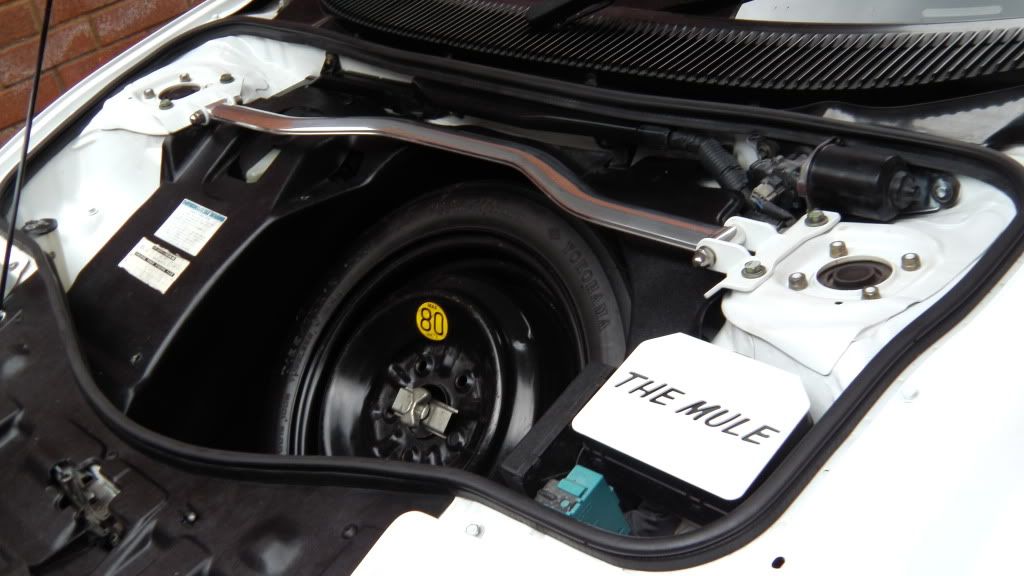

Yesterday I took delivery of a load of freshly powder coated bits.

I chose Arctic White as the colour, as their brief was

"Use the whitest white you have".

The brackets for the Cusco front brace

Assembled

Rear brace next

I'm thrilled with how they turned out! The colour is a perfect white for the car, which I was a little worried about

There's a few other bits too, but we'll get to them later.

.

Meanwhile, back to the car.

Front end removed from it's cover and back on the ground

The same for the back.

It's getting close now

It lives!

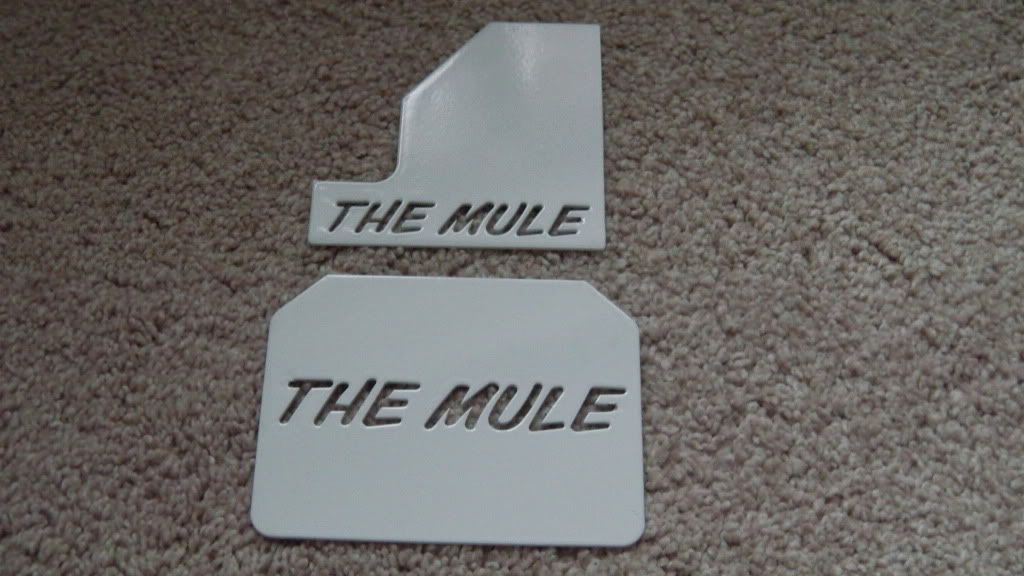

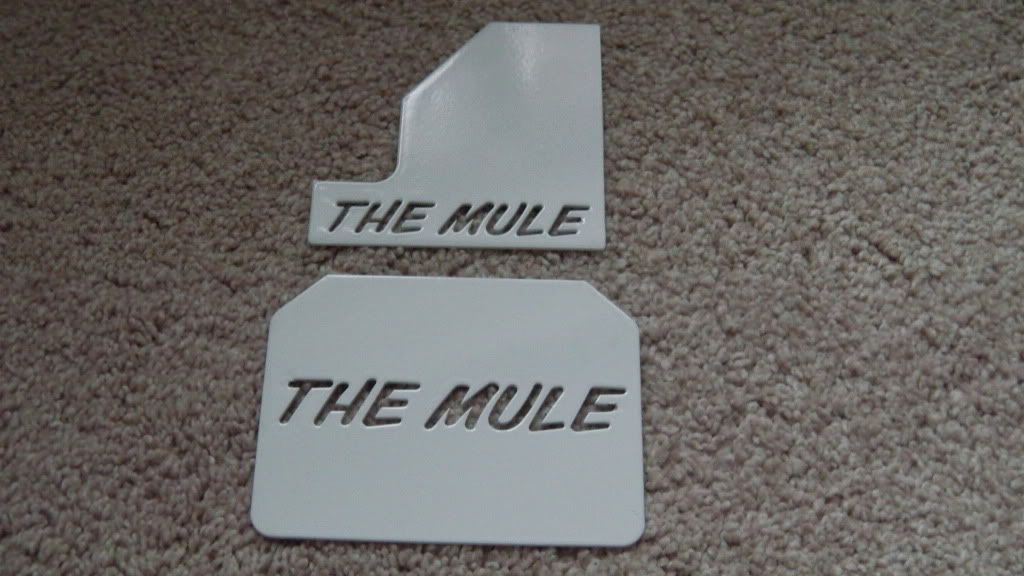

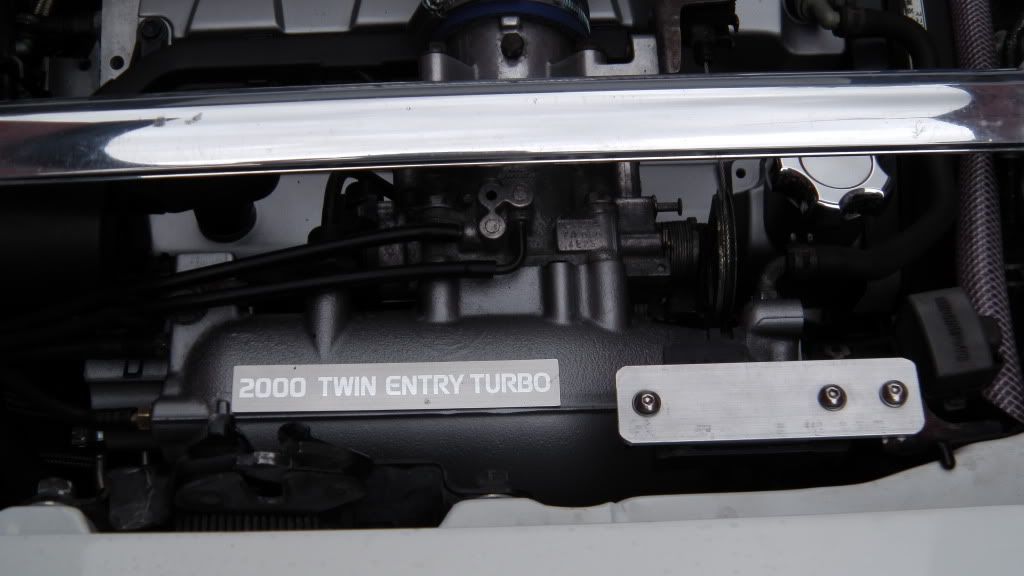

Well, now it's alive it's only fitting that any living thing have a name.

But what to call it

I think we all knew what it would be.

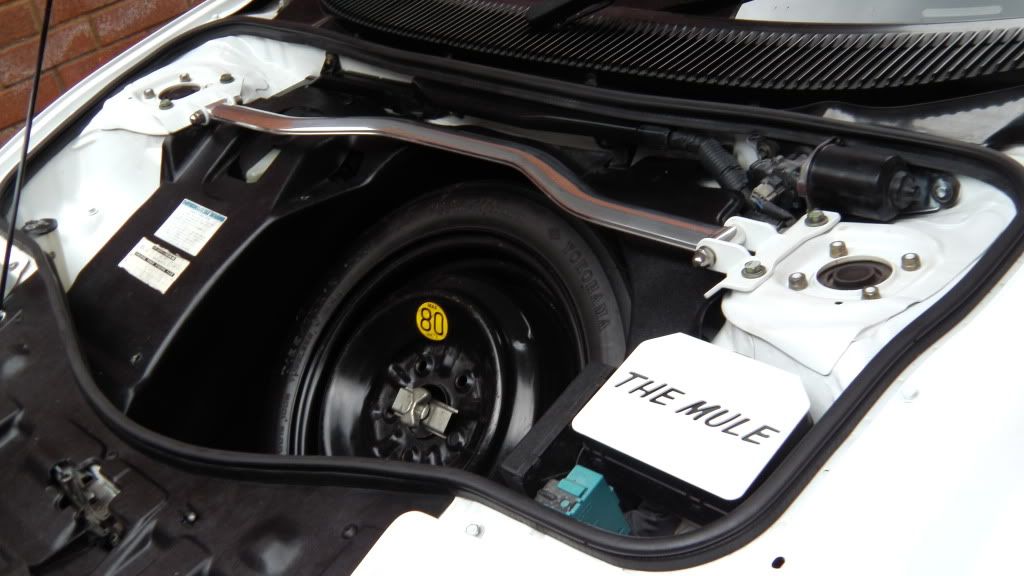

There was never any doubt in my mind as to it's identity and now it's alive it needs it's name badge back.

This time with a fresh powdery coat, to reflect it's beautiful new physique.

I guess we need to get these bits mounted then, as I suppose you'll all be wanting to see the finished article

The front before

(terrible phone picture

)

And now

Splendid

I also had a little something done for the interior.

I wasn't happy with where the EVC was mounted and besides, I did spend hours making this thing

Fitted and matching perfectly

(minus the pearl finish of course)

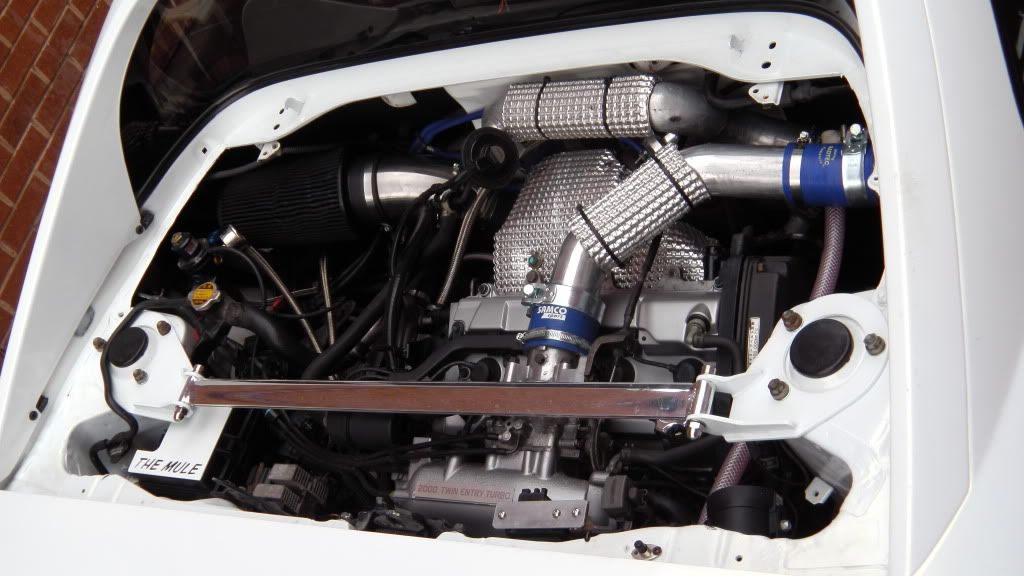

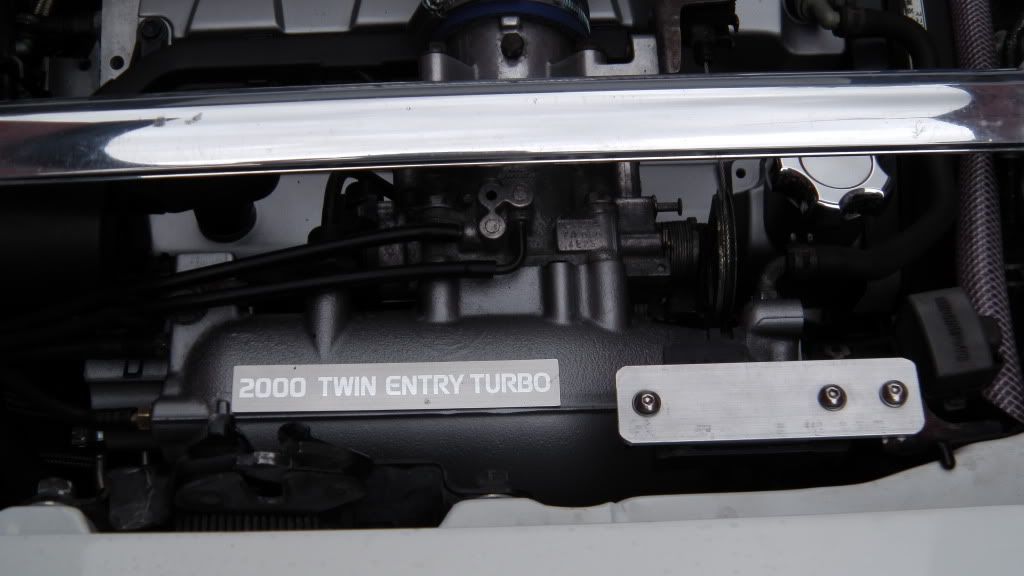

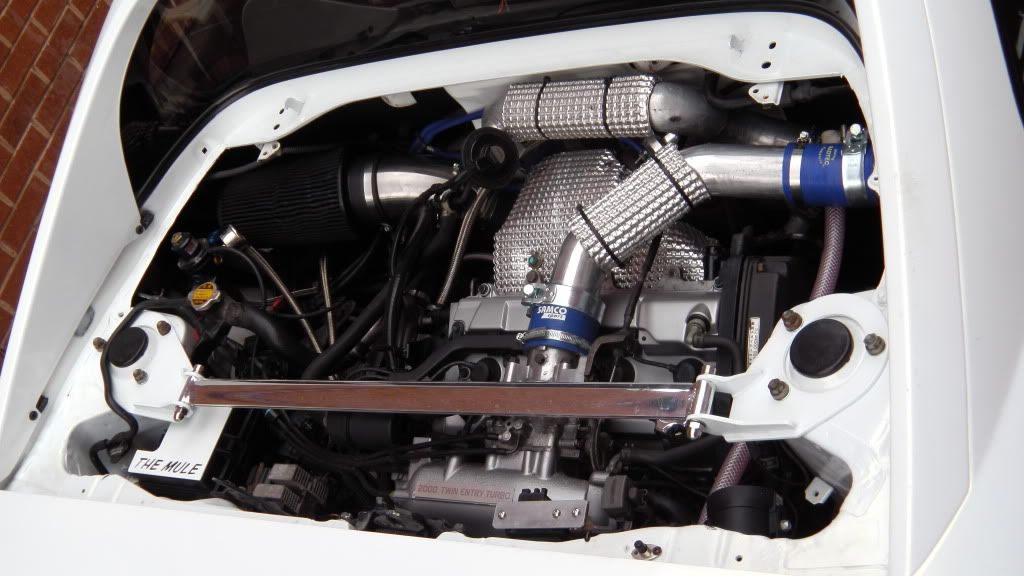

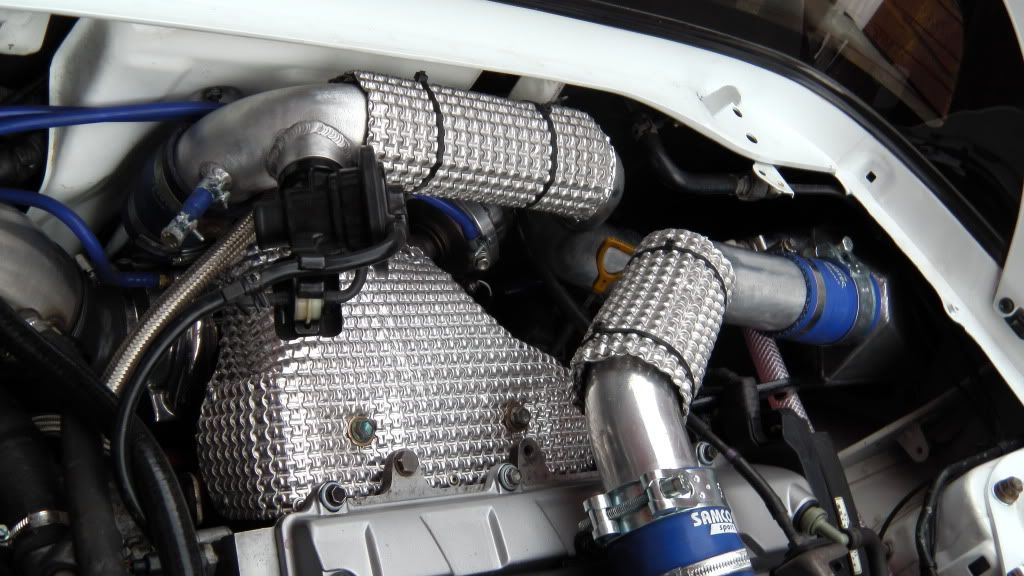

So I guess it's time to move onto the main event, the heart of the beast.

So after many weeks of planning, countless hours of hard work from Peter, blood

(mainly mine), sweat, no tears though

(I'm a man after all), ladies and gentlemen: I give you

'The Mule'

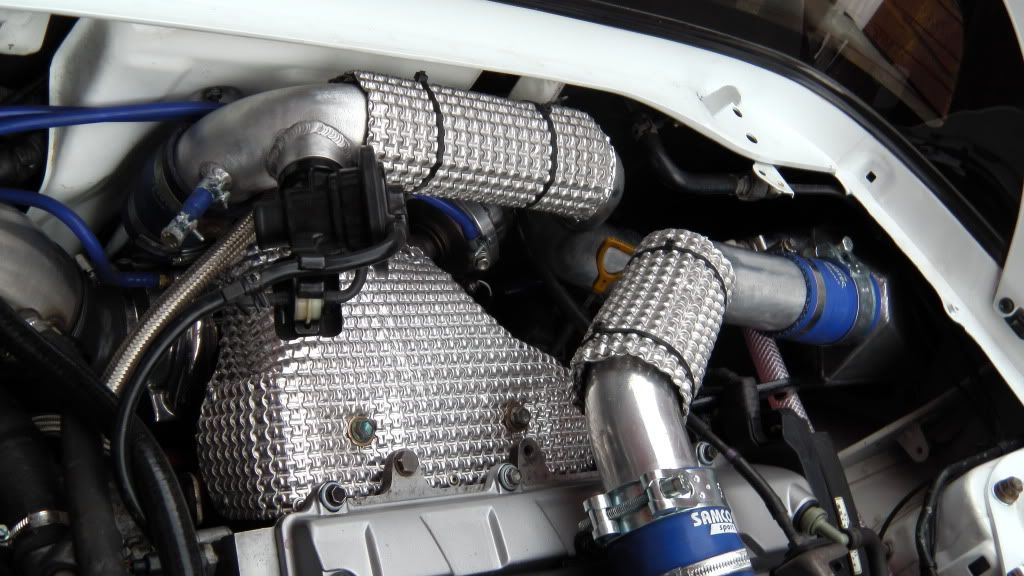

FPR in place, with the luxury of it being able to sit proud of where the lid would normally be

I'm over the moon with how it's turned out!

Peter had artistic license when it came to replacing seals, bearing, bushing, any mechanical really.

We both wanted this engine

(and car as a whole) fully sorted, with no issues of any kind.

Peter's put in some serious hard work and late nights and has gone the extra mile on all aspects of this project.

Something for which I'm massively grateful for

It was also his idea to replace the blue hoses

(which worked well on the blue car) with black throughout, apart from the air lines.

It works, it looks get and suits the overall monochrome look of the car perfectly

(in my eyes).

So how does it handle? It's perfect! The combination of refurbing the calipers, adding the Carbotechs, Goodridge lines, Cusco pillow balls, Toms under body brace, new track rod ends and four wheel alignment, mean the chassis and brakes are fully sorted.

This thing's planted! No more dodgy brakes, wheel shake, vague handling and generally unforgiving feel to the drive.

Sit, steer, go and enjoy

And the power? Mother of god it pulls hard! With the standard engine it was a pretty quick car, but it had the same feel as you're average quick everyday car.

Now though with the old engine, which was already a bit of a weapon, but now with the timing, cams, shims etc etc sorted, it's brutally quick.

The best thing now is that it has the handling and grip to utilise all the power.

Stamp on the

"Go" pedal in 2nd gear and there's no tyre spinning, it just goes.

I guess this is where the 275s come into their own

I couldn't be happier with the car I've got now.

It's been a long and winding 9 months since I started my

'2 journey and there's certainly been some highs and lows.

Now though it's all written into history.

What's next? Sufficed to say I have a few things in the pipeline

I need to finish wrapping the pipework, probably using Nimbus and heat wrap but one solid piece of Nimbus.

It wouldn't be the same if it didn't take 10 hours to make that perfect piece now would it

I guess I should stop rambling on now, as I'm bored of typing and you're probably bored of reading

Thanks again to you Peter, you can get some sleep now

I have developed a love of doing all the detail and custom work though.

Something I'd like to explore more in the future I think

Well, if you do, take pictures of the before and after shots of her face then your face

Lol

Lol