Tim

Fitting new rear arches

Moderators: IMOC Moderators, IMOC Committee Members

Fitting new rear arches

When you are replacing the rear arches do you cut out the rusty bits  & weld the new panel on top of what's left

& weld the new panel on top of what's left  & after grinding down the weld, hide the lip with a skim of filler or do you try

& after grinding down the weld, hide the lip with a skim of filler or do you try  & get the cut exactly to allow you to butt weld the new panel to the old.

& get the cut exactly to allow you to butt weld the new panel to the old. The first option would be the easiest for me but a friend has restored a Fiat 128 3p

The first option would be the easiest for me but a friend has restored a Fiat 128 3p  & he butt welded all the repair pieces.

& he butt welded all the repair pieces. What have others done?.

What have others done?.

Tim

Tim

Re: Fitting new rear arches

First option for me, I brazed the new panel and now I'm rubbing the filler back. I suppose it depends what condition your arches are in and where you can find good metal

I suppose it depends what condition your arches are in and where you can find good metal

Re: Fitting new rear arches

I'll be butt welding mine when i finally get round to doing them.

Re: Fitting new rear arches

First option for me as well. With the profile it's hard to cut'n'shut exactly to get a butt weld.

With the profile it's hard to cut'n'shut exactly to get a butt weld.

I used a joddler to put a step in the new metal so the final surfaces line up exactly.

After you've ground the welds flush there's very little filler in the final arch and it's quite a strong job.

After you've ground the welds flush there's very little filler in the final arch and it's quite a strong job.

I used a joddler to put a step in the new metal so the final surfaces line up exactly.

-

classic mk1

Re: Fitting new rear arches

Never butt weld 2 thin pieces together, its extremely difficult to control the temp of the weld even more so if using mig. If using a mig use 0.6 wire with gas, overlap the sections to be welded

If using a mig use 0.6 wire with gas, overlap the sections to be welded  .

. Using welding clamps to keep the joint tightly closed tack weld at close intervals.

Using welding clamps to keep the joint tightly closed tack weld at close intervals. Then keeping the heat build up to a minimum first weld at front of the arch then the rear to much heat in the panel and you will create a dent or buckle.

Then keeping the heat build up to a minimum first weld at front of the arch then the rear to much heat in the panel and you will create a dent or buckle. Dont be tempted to use gase less wire as you will strugle to fine tune the welder and end up with too much heat and weld to grind off.

Dont be tempted to use gase less wire as you will strugle to fine tune the welder and end up with too much heat and weld to grind off. If the thickness of the material to be welded is about 2-3mm and above butt welding is possible.

If the thickness of the material to be welded is about 2-3mm and above butt welding is possible.

If the joint / overlap is pull together tightly when welding and the weld ground flush the job will only require a thin skim of filler and you wont notice its been overlapped.

/ overlap is pull together tightly when welding and the weld ground flush the job will only require a thin skim of filler and you wont notice its been overlapped.

If the joint

Re: Fitting new rear arches

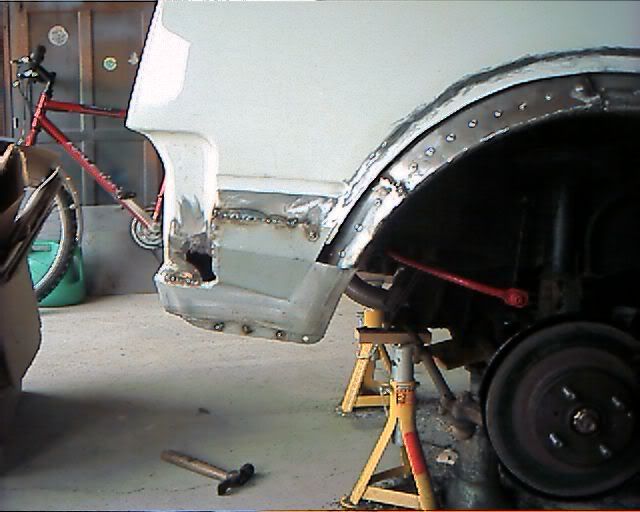

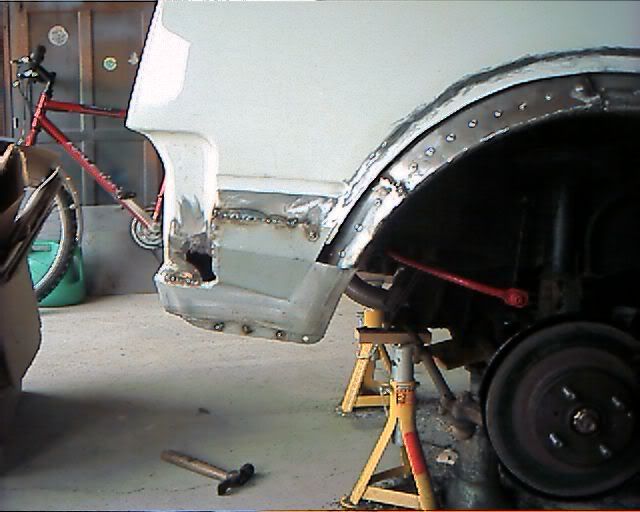

Here's a few pics of how I did mine. Basically the easiest way.

Basically the easiest way. I had to build a new inner arch as you can see in the pics.

I had to build a new inner arch as you can see in the pics. The line around the arch is were we welded the new arch to.

The line around the arch is were we welded the new arch to. Also using clamps you can get the arch to sit were you want before you start welding.

Also using clamps you can get the arch to sit were you want before you start welding.

-

classic mk1

Re: Fitting new rear arches

Hi, i wouldnt recommend arc welding on thin material. You will find it impossible to control the weld pool and end up with more holess than wing.

You will find it impossible to control the weld pool and end up with more holess than wing. As people have already suggested to you brazing or mig are the prefered methods base on their previous experiences.

As people have already suggested to you brazing or mig are the prefered methods base on their previous experiences.