v6 turbo

Moderators: IMOC Moderators, IMOC Committee Members

Re: v6 turbo

Yep. .

. .sound clip needed on start up.

.sound clip needed on start up.

T

T

-

whoozy

Re: v6 turbo

No mager development,but a bit of kit for the engine,

430cc injectors for 7M-GTE engined Toyota Supra

430cc injectors for 7M-GTE engined Toyota Supra

-

whoozy

Re: v6 turbo

time for an update! we now have a fidanza fly and clutchmasters fx400 clutch! better late than never i suppose. .

. .

. .

.

And the engine is looking more complete now. .

. .

.

oil feed line for the turbo is fitted. .

. .

.

so paul now has everything he need to nail this sucker together

here is my engine and gearbox loaded onto the dolly. .

. .

. .

.

But before this could be fitted to the car we had a few jobs to do that would be hard when the engines fitted,firstly the fusebox needed lowering,this was to let the IC pipework that runs from turbo to IC sit above it. .

. .

.

It actually relocated very easily,theres a spare bolt hole in exactly the right place lower down and paul rewelded the clip in bracket lower down on the strut tower.

Next up was IC fitment,this needed to sit exactly where paul wants it to go. .

. .so he made a big bracket that straps around the IC and bolts to a bracket that i relocated higher up on the strut tower.

.so he made a big bracket that straps around the IC and bolts to a bracket that i relocated higher up on the strut tower. .

. .

.

you can see here we also have plenty of room for a fan under the IC. .

. .

. .

.

tomorrow the engine finally goes in and we start to plan the turbo install

ok today we hit a major bloody obstacle! one that threatened to put an end to pauls plans for the boot mounted turbo and IC position that he'd already spent a shitload of time and money on. .

. .it was the turbo oil return line.

.it was the turbo oil return line.

Any turbo oil return line only has a few requirements. .

. .

. .

.

1/ it is of big enough bore to carry away oil from the turbo to the sump without restriction

2/ it must travel downhill from the turbo all the way

3/ it cannot be submerged in oil at the sump and must remain above the oil level

if you dont adhere any of the above it can cause big problems!

So here was the problem,with the v6 fitted paul couldnt find a path around the engine from the turbo position in the boot and onto the sump fitting on the front of the engine. .

. .

. .not without going uphill over the engine mount which is a no no.

.not without going uphill over the engine mount which is a no no. .

. .

. .

. .he just couldnt find a way through! everything was in pauls way no matter what.

.he just couldnt find a way through! everything was in pauls way no matter what.

So desperate times call for desperate measures. .

. .

. .

. .the squeamish should look away now!

.the squeamish should look away now!

What we did and in fact HAD to do was open one side of the chassis leg and route the oil return line through the chassis leg! we did this with copper tubing as it will never rot,therefore no future problems inside the chassis and its maintenance free,it travels downhill so thats that box ticked and most importantly of all its going to work! without doing it this way we would have to rethink the entire turbo set up.

Here is the chassis welded back up and we have sealed the welds up with seam sealer and also seam sealed around the return line,this still needs to be painted as well. .

. .

. .

. .

. mad or a stroke of genius? you decide!

mad or a stroke of genius? you decide!

At each end of this pipe we will run rubber to the sump and onto the turbo oil outlet so no movement at all on the "chassis pipe" as we now call it

"chassis pipe" as we now call it

And the engine is looking more complete now.

oil feed line for the turbo is fitted.

so paul now has everything he need to nail this sucker together

here is my engine and gearbox loaded onto the dolly.

But before this could be fitted to the car we had a few jobs to do that would be hard when the engines fitted,firstly the fusebox needed lowering,this was to let the IC pipework that runs from turbo to IC sit above it.

It actually relocated very easily,theres a spare bolt hole in exactly the right place lower down and paul rewelded the clip in bracket lower down on the strut tower.

Next up was IC fitment,this needed to sit exactly where paul wants it to go.

you can see here we also have plenty of room for a fan under the IC.

tomorrow the engine finally goes in and we start to plan the turbo install

ok today we hit a major bloody obstacle! one that threatened to put an end to pauls plans for the boot mounted turbo and IC position that he'd already spent a shitload of time and money on.

Any turbo oil return line only has a few requirements.

1/ it is of big enough bore to carry away oil from the turbo to the sump without restriction

2/ it must travel downhill from the turbo all the way

3/ it cannot be submerged in oil at the sump and must remain above the oil level

if you dont adhere any of the above it can cause big problems!

So here was the problem,with the v6 fitted paul couldnt find a path around the engine from the turbo position in the boot and onto the sump fitting on the front of the engine.

So desperate times call for desperate measures.

What we did and in fact HAD to do was open one side of the chassis leg and route the oil return line through the chassis leg! we did this with copper tubing as it will never rot,therefore no future problems inside the chassis and its maintenance free,it travels downhill so thats that box ticked and most importantly of all its going to work! without doing it this way we would have to rethink the entire turbo set up.

Here is the chassis welded back up and we have sealed the welds up with seam sealer and also seam sealed around the return line,this still needs to be painted as well.

At each end of this pipe we will run rubber to the sump and onto the turbo oil outlet so no movement at all on the

-

whoozy

Re: v6 turbo

well yesterday being a bank holiday paul thought  **** it,im not going to spend it sitting at home watching another repeat of a james bond film,so he went to work and got quite a lot done.

**** it,im not going to spend it sitting at home watching another repeat of a james bond film,so he went to work and got quite a lot done.

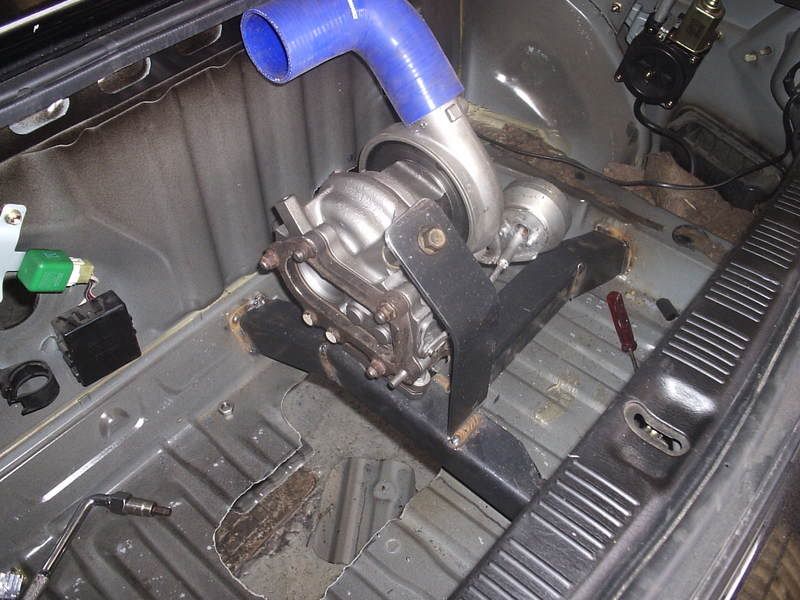

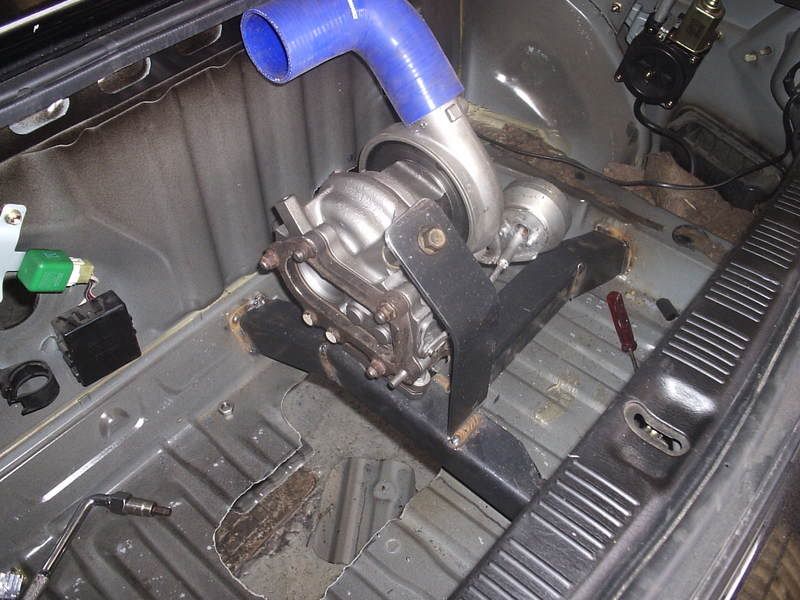

He needed to get the turbo fitted before the engine goes in so that he can fab everything up properly,paul started by plasma cutting out the holes for the water and oil feeds. .

. .

. .this is just rough for now,it will all be smoothed later.

.this is just rough for now,it will all be smoothed later. .

. .

. .

.

And also cut out the boot floor where the exhaust will roughly enter and exit the turbo. .

. .

.

he he arent plasma cutters fun!

next he mocked up the turbos position. .

. .

. .

.

From here on it was a matter of building a secure frame for it to bolt to,the first brace runs from front to back and catches two of the turbo flange bolt holes. .

. .

. .

.

and with the turbo bolted to it. .

. .

.

The next brace runs perpendicular to the first and onto the chassis rail,this one catches another turbo flange hole and stiffens the first bracket. .

. .

. .

.

By now the whole thing is very solid,the third and final brace runs from the first and catches a nice big bolt hole in the turbo. .

. .

. .

.

So thats the turbo mounted,we will put two flexi pipes on the exhaust going into this so nothing can crack.

Here is the view under the car,this is where the exhaust will enter from the engine to turbo. .

. .and also where it will rejoin the exhaust system which is all going to be scratch fabricated out of a new turbo magnex system

.and also where it will rejoin the exhaust system which is all going to be scratch fabricated out of a new turbo magnex system

So quite a lot of progress today and the turbo outlet pipe is in exactly the right position.We will make a lot of nice aluminium shields for the turbo and pay attention to detail on the holes we have cut

right paul made quite good progress yesterday,all of it totally devoted to exhaust work and making a v6 turbo downpipe!

here is one brand new mk2 turbo magnex system. .

. .

. .

. .

.

What do we do with it? chop it up of course!!

This thing was going to be a complete custom fit so he needed the exhaust in its component parts.First job was to hang one of the rear silencers,paul did this by suspending it on coathangers welded to the boot floor,then by bending the coathanger you can adjust the height and orientation of the silencer. .

. .

. .

.

And viewed from the rear. .

. .

. .

.

The back panel is coming off this car so it will look a lot better removed,for now its helping us line the exhaust up.

Here is both silencers hung where they need to go. .

. .

.

Now paul needed to make a fresh Y section from scratch where both silencers get fed by the turbo. .

. .

. .

. these are just tacked in place for now.

these are just tacked in place for now.

Next he had to fabricate a join into the system,this will let the rear section unbolt from the car separately from the downpipe section coming from the turbo,very important! last thing paul would want is for me to have problems removing the exhaust in years to come. .

. .

. .

.

Then paul made the turbo downpipe itself that bolts to this flange. .

. .

. .

. first just the downpipe bit.

first just the downpipe bit. .

. .

. .

.

And then he made the wastegate section of the downpipe. .

. .

. .

.

So it just needs a little end cap on it now to seal it up,paul was able to check wastegate flap operation with a compressed air line to make sure it wasnt catching on anything.

The complete downpipe. .

. .

. .

.

Thats a massive job out of the way,nothing stopping the engine going in now

The plan here is to check the turbo works and all is well on the stock injectors and ecu,just temporarily,then when paul knows everything is ok he will stick the supra injectors in,fire it up briefly to check for fuel leaks and when thats ok it will be time to load it onto a trailer to go to tracktive for the hydra fitting and mapping,thats the plan anyway.

ok heres todays madness,paul started by redoing the downpipe wastegate section. .

. .

. .

. .

.

Now isnt that better,not sure what he was thinking first time around. .

. .lol

.lol

An old friend of pauls used to say if something looks right it IS right. .

. .

.

Next job was to make the turbo to IC pipe,nothing flash,just a pipe with a 90* bend in it that goes through a hole paul cut in the firewall. .

. .

. .

.

And where it joins onto the IC. .

. .

. .you can really start to see it all come together now.

.you can really start to see it all come together now. .

. .

.

Now before the engine goes in he fitted the coilpack. .

. .

.

And with that out of the way he took an hour out to finish welding up the exhaust system from the downpipe rearwards. .

. .

.

Then there was nothing else for it but to install the engine. .

. .

. .here it is on its way up.

.here it is on its way up. .

. .

. .

.

And sitting bolted in place. .

. .

. .

.

You can see how nicely the IC outlet is going to mate up with the throttle body,looks almost meant to be. .

. .

. .

. not bad for a Saab part!

not bad for a Saab part!

He needed to get the turbo fitted before the engine goes in so that he can fab everything up properly,paul started by plasma cutting out the holes for the water and oil feeds.

And also cut out the boot floor where the exhaust will roughly enter and exit the turbo.

he he arent plasma cutters fun!

next he mocked up the turbos position.

From here on it was a matter of building a secure frame for it to bolt to,the first brace runs from front to back and catches two of the turbo flange bolt holes.

and with the turbo bolted to it.

The next brace runs perpendicular to the first and onto the chassis rail,this one catches another turbo flange hole and stiffens the first bracket.

By now the whole thing is very solid,the third and final brace runs from the first and catches a nice big bolt hole in the turbo.

So thats the turbo mounted,we will put two flexi pipes on the exhaust going into this so nothing can crack.

Here is the view under the car,this is where the exhaust will enter from the engine to turbo.

So quite a lot of progress today and the turbo outlet pipe is in exactly the right position.We will make a lot of nice aluminium shields for the turbo and pay attention to detail on the holes we have cut

right paul made quite good progress yesterday,all of it totally devoted to exhaust work and making a v6 turbo downpipe!

here is one brand new mk2 turbo magnex system.

What do we do with it? chop it up of course!!

This thing was going to be a complete custom fit so he needed the exhaust in its component parts.First job was to hang one of the rear silencers,paul did this by suspending it on coathangers welded to the boot floor,then by bending the coathanger you can adjust the height and orientation of the silencer.

And viewed from the rear.

The back panel is coming off this car so it will look a lot better removed,for now its helping us line the exhaust up.

Here is both silencers hung where they need to go.

Now paul needed to make a fresh Y section from scratch where both silencers get fed by the turbo.

Next he had to fabricate a join into the system,this will let the rear section unbolt from the car separately from the downpipe section coming from the turbo,very important! last thing paul would want is for me to have problems removing the exhaust in years to come.

Then paul made the turbo downpipe itself that bolts to this flange.

And then he made the wastegate section of the downpipe.

So it just needs a little end cap on it now to seal it up,paul was able to check wastegate flap operation with a compressed air line to make sure it wasnt catching on anything.

The complete downpipe.

Thats a massive job out of the way,nothing stopping the engine going in now

The plan here is to check the turbo works and all is well on the stock injectors and ecu,just temporarily,then when paul knows everything is ok he will stick the supra injectors in,fire it up briefly to check for fuel leaks and when thats ok it will be time to load it onto a trailer to go to tracktive for the hydra fitting and mapping,thats the plan anyway.

ok heres todays madness,paul started by redoing the downpipe wastegate section.

Now isnt that better,not sure what he was thinking first time around.

An old friend of pauls used to say if something looks right it IS right.

Next job was to make the turbo to IC pipe,nothing flash,just a pipe with a 90* bend in it that goes through a hole paul cut in the firewall.

And where it joins onto the IC.

Now before the engine goes in he fitted the coilpack.

And with that out of the way he took an hour out to finish welding up the exhaust system from the downpipe rearwards.

Then there was nothing else for it but to install the engine.

And sitting bolted in place.

You can see how nicely the IC outlet is going to mate up with the throttle body,looks almost meant to be.

Re: v6 turbo

Wow

Thats really coming together now.

Thats really coming together now.

Cant wait to see it finished

When will it be running ?

?

Cant wait to see it finished

When will it be running

Re: v6 turbo

i have been watching this day by day and i am really impressed,

Great to see projects like this, looks amazing quality is great and really hopes it all works out bud, best of luck

Great to see projects like this, looks amazing quality is great and really hopes it all works out bud, best of luck

-

whoozy

Re: v6 turbo

Munnsy wrote:i have been watching this day by day and i am really impressed,

Great to see projects like this, looks amazing quality is great and really hopes it all works out bud, best of luck

Thanks dude

-

mr2greasemonkey

nice

Hey that's looking pretty good. Looks like you guys spent a lot of time figuring stuff out.

Looks like you guys spent a lot of time figuring stuff out. Interesting placement of the turbo and IC.

Interesting placement of the turbo and IC. I noticed where you guys cut holes in the rear frame rails.

I noticed where you guys cut holes in the rear frame rails. Did you re-inforce that section? I've seen quite a few mr2's that have been rear ended and that is usually where the rails buckle.

Did you re-inforce that section? I've seen quite a few mr2's that have been rear ended and that is usually where the rails buckle. Good job on the exhaust fab work.

Good job on the exhaust fab work. Engine looks great in red.

Engine looks great in red.

Re: v6 turbo

Absolutely stunning.

How much for everything including parts and labour?

How much for everything including parts and labour?

-

whoozy

Re: v6 turbo

mr2nut123 wrote:Absolutely stunning.

How much for everything including parts and labour?

Way over

Re: v6 turbo

Stunning project!

Where will the air filter and intake pipe run? Doesn't look like there's much room left in the engine bay, unless it going straight down from the turbo through the boot floor?

Where will the air filter and intake pipe run? Doesn't look like there's much room left in the engine bay, unless it going straight down from the turbo through the boot floor?

-

whoozy

Re: v6 turbo

mattcambs wrote:Stunning project!

Where will the air filter and intake pipe run? Doesn't look like there's much room left in the engine bay, unless it going straight down from the turbo through the boot floor?

Its going to sit next to the turbo,some body mods are being made up to have a vent on either side going into the boot,and a scooby bonet scoop on the boot to let heat out followed with two fans in the boot as well.

-

whoozy

Re: v6 turbo

well today i got the IC to TB pipe fabbed up,this pipe needed to accommodate the BOV and also the ISCV bypass hose.

First job was to find a piece of pipe that ran nicely from the IC to TB. .

. .

. .

.

This one had the perfect bore and bend on it to suit.Next job was to weld a pipe onto it for the HKS bov to attach to. .

. .

. .

.

And with the BOV fitted. .

. .

. .

.

Next job was to weld another fitting in for the ISCV bypass pipe. .

. .

. .

. .then a steel lined pipe was attached to this and onto the original bypass rubber hose.

.then a steel lined pipe was attached to this and onto the original bypass rubber hose. .

. .

. .

.

These pipes all need clips and pipes painting but the basic fitting up is there now

First job was to find a piece of pipe that ran nicely from the IC to TB.

This one had the perfect bore and bend on it to suit.Next job was to weld a pipe onto it for the HKS bov to attach to.

And with the BOV fitted.

Next job was to weld another fitting in for the ISCV bypass pipe.

These pipes all need clips and pipes painting but the basic fitting up is there now

-

whoozy

Re: v6 turbo

todays update. .

. .

. paul spent time lining the IC pipe hole and also the water and oil feed lines for the turbo,its basically vac pipe sliced down the middle,filled with mastic and stuck on the hole edge,works perfectly though.

paul spent time lining the IC pipe hole and also the water and oil feed lines for the turbo,its basically vac pipe sliced down the middle,filled with mastic and stuck on the hole edge,works perfectly though. .

. .

. .

.

Next he painted the IC pipes,gloss black. .

. .

. .check out the shine on these fellas,the spray gun was on form for sure.

.check out the shine on these fellas,the spray gun was on form for sure. .

. .

.

Next job was making the radiator pipes fit,nothing special,just join A to B. .

. .

. .

.

next job was intercooler fan,we are using one off a GSXR1100 here,these little fans spin like a ferking bostard (no problem paul) lol again its partially secured onto the IC strap by two bolts,ive also had to extend its wiring.

(no problem paul) lol again its partially secured onto the IC strap by two bolts,ive also had to extend its wiring.

Next the ECU was mounted,we had to mount this much lower than normal to clear the IC pipe.

Now time to sort cooling,paul chopped a big hole in the boot lid,,taking a plasma cutter to a perfectly good mk2! lol and inserted a scoobaru vent in. .

. .

.

.

. .

. .then a very strong fan will suck hot air out of the boot as well as air being sucked out of the vent normally when driving due to aerodynamics.

.then a very strong fan will suck hot air out of the boot as well as air being sucked out of the vent normally when driving due to aerodynamics.

There will be two scoops on the quarters taking air in also,one of which will have a fan on it for sucking air in when the cars idle. .

. .

. .

. .see i thought of everything

.see i thought of everything

Finally today here is the intake pipe,this needs cutting to length and the air filter sticking on it. .

. .

. .for now paul will need to ditch this and plumb up the old AFM just to fire the engine up and check everything works.

.for now paul will need to ditch this and plumb up the old AFM just to fire the engine up and check everything works. .

. .

. .then when we have done plenty of test runs at 3 psi ish we can ditch the AFM and fit this pipe,and also fit the supra injectors ready for its trip to tracktive for mapping the hydra ecu.

.then when we have done plenty of test runs at 3 psi ish we can ditch the AFM and fit this pipe,and also fit the supra injectors ready for its trip to tracktive for mapping the hydra ecu. .

. .

. ten zillion torques here we come

ten zillion torques here we come

today paul thought he'd make the supporting frame for both the scoop to attach to and also mount the extraction fan onto,luckily for him the hole spacing is the same on the scoop and the fan holes,so they both hit the framework he welded in. .

. .

. .the scoop was bonded in with mastic as well,very strong! the underside still needs some tidying up and painting but you get the idea.

.the scoop was bonded in with mastic as well,very strong! the underside still needs some tidying up and painting but you get the idea. .

. .

. .

.

And from the outside the finished vent. .

. .

.

Next he fitted the oil return line onto the sump from the woods patented "chassis pipe" lol we used a braided flexi line for this job.

"chassis pipe" lol we used a braided flexi line for this job. .

. .

. .

.

With half a day left paul decided to tackle the wiring,and although its not tidied away the ecu is now wired up. .

. .only other wiring thats left is the cockpit gauges and cooling fans.

.only other wiring thats left is the cockpit gauges and cooling fans. .

. .

. .

.

Next he painted the IC pipes,gloss black.

Next job was making the radiator pipes fit,nothing special,just join A to B.

next job was intercooler fan,we are using one off a GSXR1100 here,these little fans spin like a ferking bostard

Next the ECU was mounted,we had to mount this much lower than normal to clear the IC pipe.

Now time to sort cooling,paul chopped a big hole in the boot lid,,taking a plasma cutter to a perfectly good mk2! lol and inserted a scoobaru vent in.

There will be two scoops on the quarters taking air in also,one of which will have a fan on it for sucking air in when the cars idle.

Finally today here is the intake pipe,this needs cutting to length and the air filter sticking on it.

today paul thought he'd make the supporting frame for both the scoop to attach to and also mount the extraction fan onto,luckily for him the hole spacing is the same on the scoop and the fan holes,so they both hit the framework he welded in.

And from the outside the finished vent.

Next he fitted the oil return line onto the sump from the woods patented

With half a day left paul decided to tackle the wiring,and although its not tidied away the ecu is now wired up.

-

Driftlimits Performance

- IMOC Affiliated Company

- Posts: 4928

- Joined: Tue Dec 14, 2004 9:33 am

- Location: 01442 601301

- Contact:

Re: v6 turbo

Hats off to great wizard Mr.Woods!

-

pintovit

Re: v6 turbo

Great project. Very well documented so a joy to follow.

Very well documented so a joy to follow.

Very impressed. .

. .

. Things look so simple when done by skilled people!

Things look so simple when done by skilled people!

Just a simple question: what will be the effect of having the turbo so far apart from the engine? I guess there simply is no space to put it closer, so I'm not questioning your options!

Just wondering. .

. .

.

Can't wait to see it finished. Great work!

Great work!

Best of luck.

Regards,

Vítor

Very impressed.

Just a simple question: what will be the effect of having the turbo so far apart from the engine? I guess there simply is no space to put it closer, so I'm not questioning your options!

Just wondering.

Can't wait to see it finished.

Best of luck.

Regards,

Vítor

-

whoozy

Re: v6 turbo

Dont know till its tested,but should be ok.

well today it was time to refit all of the intercooler and pipework. .

. .

. .its got to come back out one final time to tidy the wiring but it was a good chance to finally check it all fits properly.

.its got to come back out one final time to tidy the wiring but it was a good chance to finally check it all fits properly. .

. .

. .

.

In pauls opinion that LOOKS powerful! Who knows what it will actually produce.

In the boot paul made a nice support bracket for the IC pipe,this is rubber mounted and has a jubilee clip as part of its construction on a section of tube that has a cut in it so that it can be ratcheted up to firmly clamp it in place,the simplest ideas are always the best!

on a section of tube that has a cut in it so that it can be ratcheted up to firmly clamp it in place,the simplest ideas are always the best!

And the whole pipe fitted to the turbo. .

. .

. .

.

After this we checked things over and decided to have a cheeky turn of the key,first with the ecu unplugged to circulate oil around the engine and turbo. .

. .

. .we gave it a good 10 whirs of the starter.

.we gave it a good 10 whirs of the starter.

Then we plugged the ecu back in and gave it a turn. .

. .

. .

.

.

. .

. .

. .she lives! it fired up and ran with zero smoke from the exhaust,seems to be running fine at the moment although we did this at 4pm tonight so didnt fully get a chance to go further.

.she lives! it fired up and ran with zero smoke from the exhaust,seems to be running fine at the moment although we did this at 4pm tonight so didnt fully get a chance to go further. .

. .

. .

. but for now it runs,the turbo is getting oil

but for now it runs,the turbo is getting oil  (we checked it was returning to the sump,which it was) so the chassis pipe is a complete success

(we checked it was returning to the sump,which it was) so the chassis pipe is a complete success

well today it was time to refit all of the intercooler and pipework.

In pauls opinion that LOOKS powerful! Who knows what it will actually produce.

In the boot paul made a nice support bracket for the IC pipe,this is rubber mounted and has a jubilee clip as part of its construction

And the whole pipe fitted to the turbo.

After this we checked things over and decided to have a cheeky turn of the key,first with the ecu unplugged to circulate oil around the engine and turbo.

Then we plugged the ecu back in and gave it a turn.