Thanks guys.

Glad I took my time instead of rushing anything.

Chilled New Years for me.

(was in NYC this time last year!!)

Got a couple of nice xmas presents from the wife, pretty happy.

New Clark workbench.

Nothing fancy but good for DIY.

Clark vice

(not shown)

and a sweet Airmaster Compressor for odd jobs.

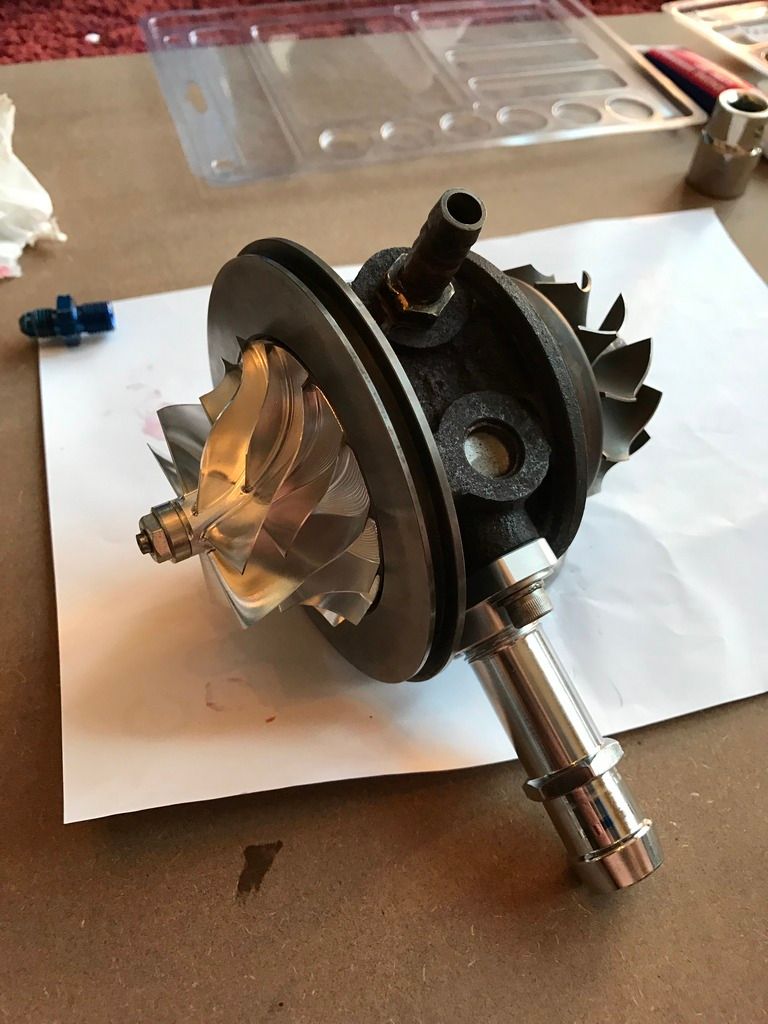

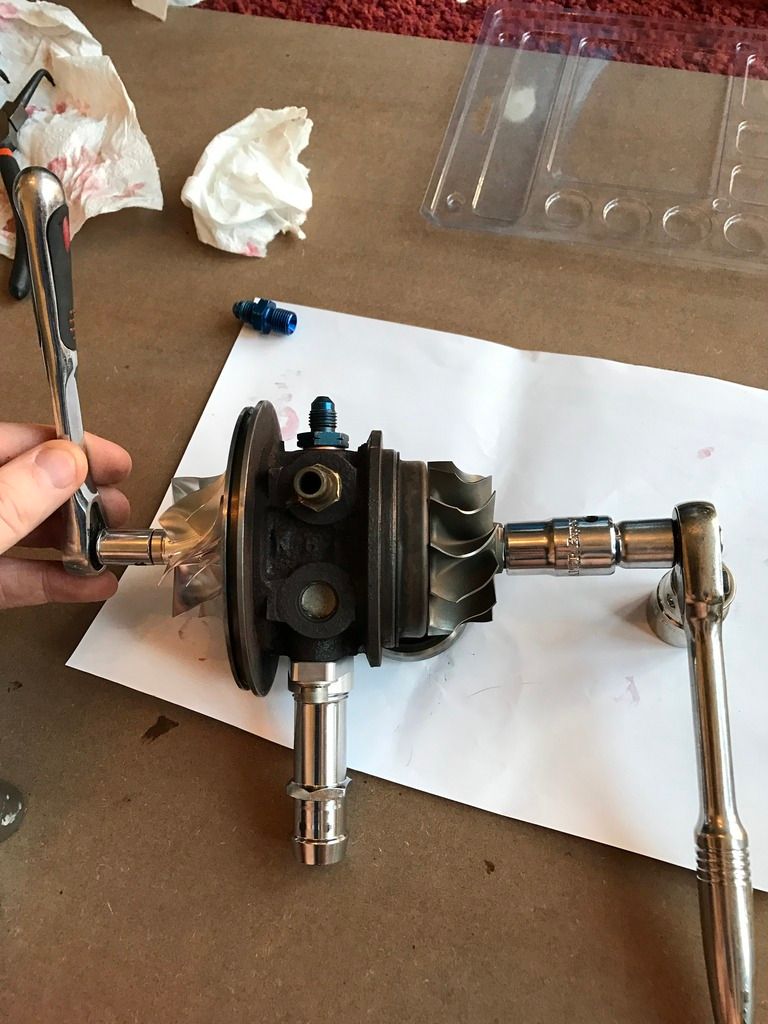

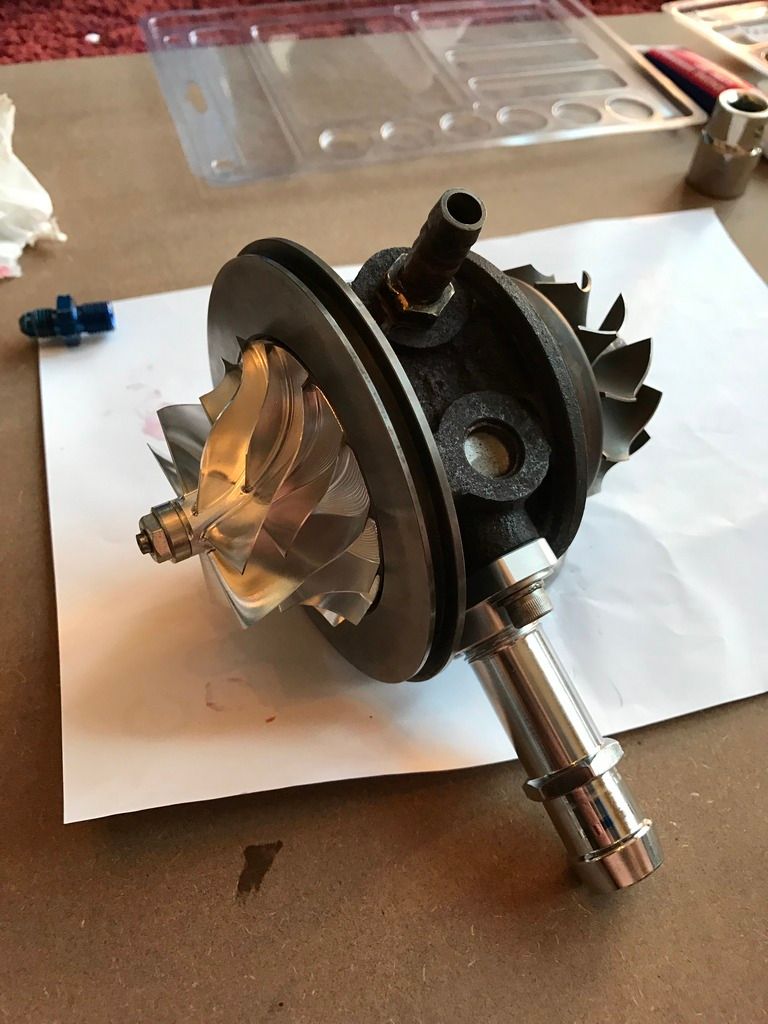

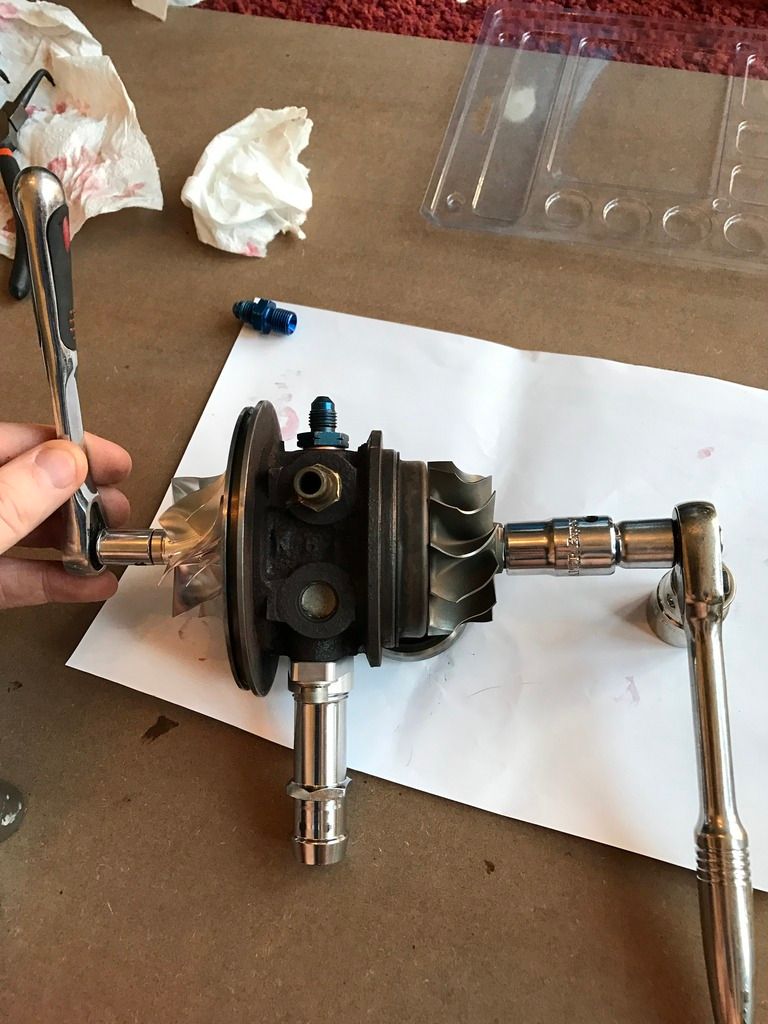

Here's a little run through with the turbo rebuild.

I used Torco essembly lube.

Parts for the task

For the uprated thrust bearing spacer i needed to ground away around 1mm from the CHRA.

Bearing in

Uprated wider thrust spacer in

Thrust bearing

Oil shield housing with outside wider spacer vs stock

New Oring fitting in CHRA before pressing this shield in, then new C clip clamping it down

New

'piston' ring on the shaft, then the other bearing

Shaft in, twist and click into place

I fitted the oil fittings whilst I was there

Also thanks to the tricks suggested, hair dryer to warm compressor wheel got this on!

Torqued to 1/4 turn as suggested my google!

ZERO shaft play now!!

Compressor housing with new Oring and C clip.

Turbine housing on with the turbine clamp, done!

Cleaned up, flat sanded all surfaces and rethreaded the adapter, down pipe, tial wastegate, turbine housing also polished the Tial wastegate slightly

Time to fit with the new nuts, washers, gaskets and studs.

Not alot of room, so needed to remove heatshields

Now unfortunately the downpipe doesn't mate well with the Berk exhaust.

Turns out common problem with the Berk, so ordering up a spacer

(i.e.

an exhaust flange with another gasket).

Bit of a hack, but ok with me.

Also need to go to a 22mm ID return oil line, as 19mm i bought won't slot over.

So won't be starting up for another week or 2.