This is going to be a mammoth build, and promises to be the highest BHP machine ever to leave Woodsport, by quite a bit!

Both walbro pumps are now installed in the tank.

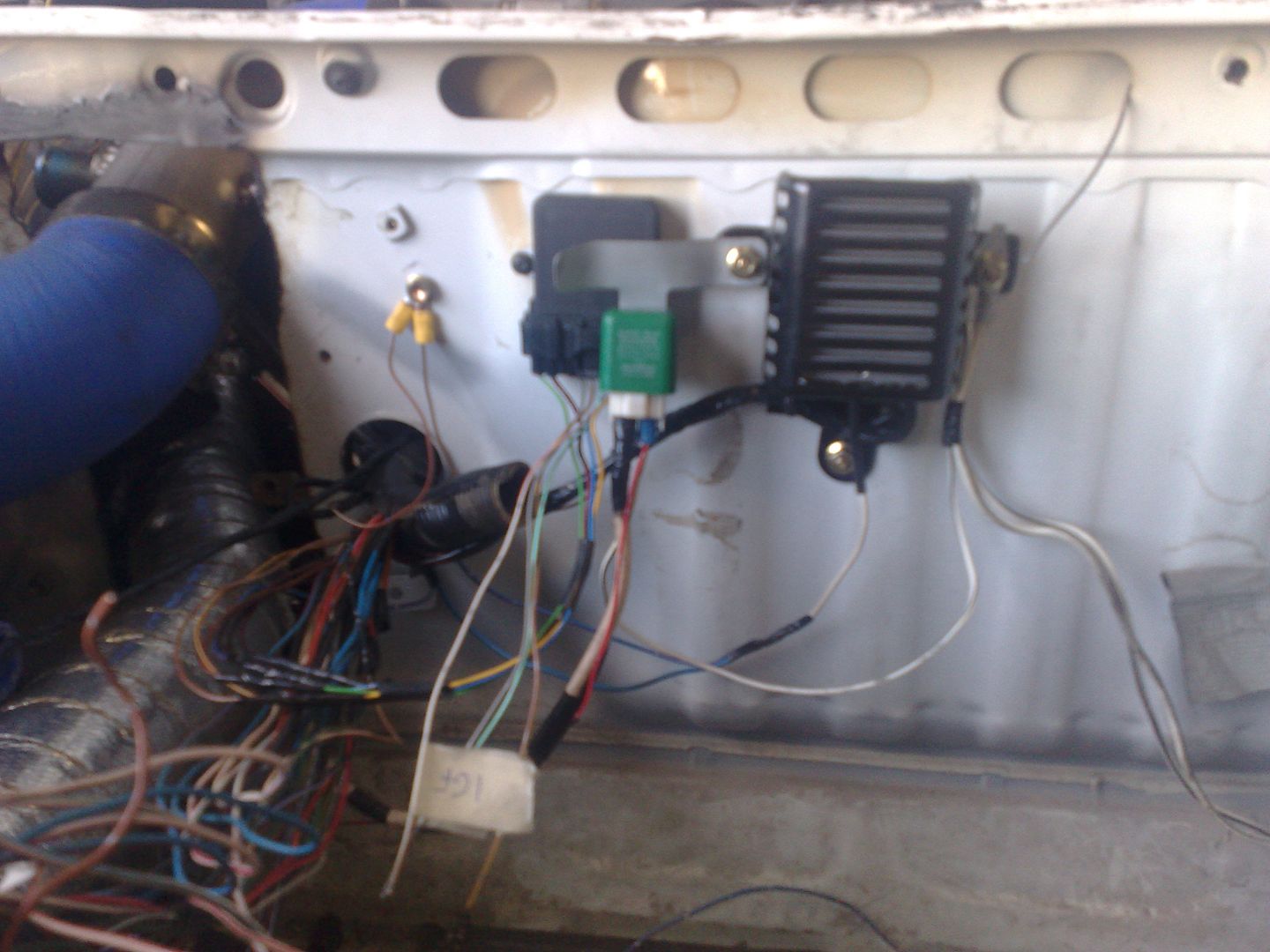

In other news Paul started extending the rear light harness, this is so he can relocate the fusebox in the engine bay to make room for other interesting stuff

Part of running a huge BHP turbocharged v6 monster is keeping things cool, more importantly the intake charge, so some serious cooling was called for, prepare to meet the chargecooler from hell.

Im told this monster, nicknamed

Its so f'kin huge this was pretty much the only place we can mount it was in the boot as the engine bay isnt big enough for both the engine/turbo and cooler, and thats without all the plumbing running between them all! so this location isnt out of choice, its the ONLY place it will go, but its a nice neat

We just sit staring at it sometimes in awe

Here is the access hole Paul cut in the rear wall for the CC pipes to enter the engine bay,these need fine trimming and dressing but you get the idea.

So thats the fridge's position mocked up,want to see the CC again? ok.

When I first showed Paul this thing he was shaking his head in disbelief!

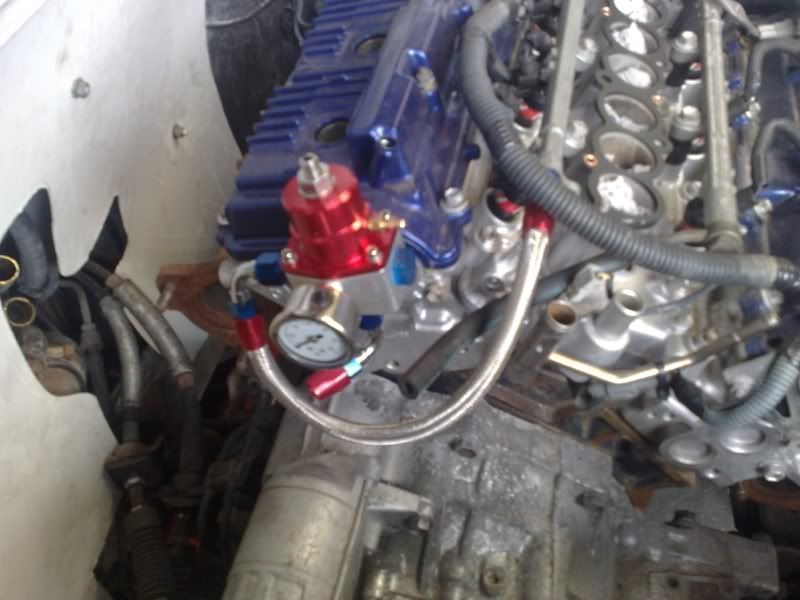

Paul turned his attention to the engine detailing, starting with cam covers, painted in Toyota Royal Sapphire Pearl

And here is the engine in its current state.

Also Paul welded the oil return into the sump.

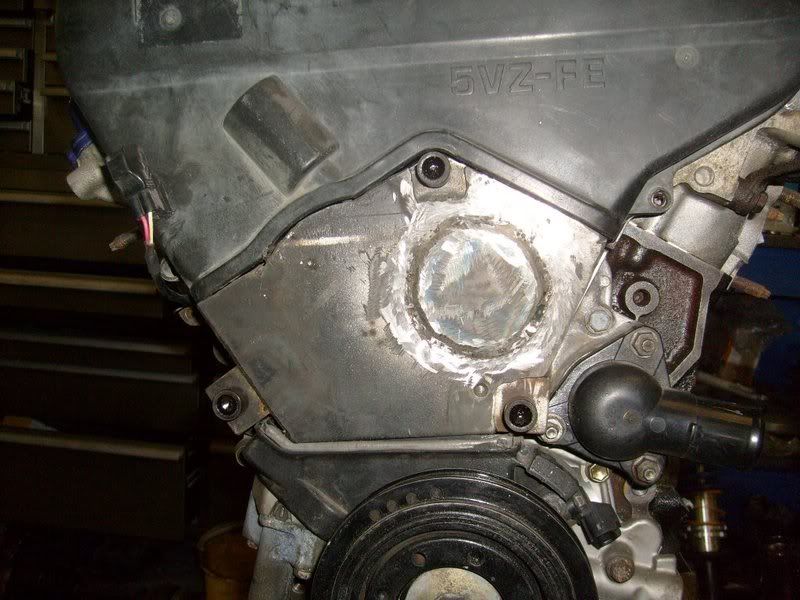

The engine bay was given a respray, it was in a bad state and no mistake and afterwards, the bay has a nice monster 5VZ-FE hanging in it.

Paul got this huge turbo mounted where it keeps everything happy.

Paul made a preliminary bracket that takes the bulk of the weight, he's also going to add various support brackets as it takes shape, but for now this has the turbo sitting where he wants it.

The turbo is puroseful though.

67.8mm inducer

94.0mm exducer

52 trim

0.72A/R

77.0mm Wheel Diameter

78 trim

1.06A/R

Free floar

0.95A/R Turbine housing.

Suffice to say, that this will be pushing around 65lb/min which we're hoping will be north of 550bhp, but very drivable with positive boost from 2400rpm and holding easily to the red line.

This is the main plenum tube, its 100mm diam, and should be around 400mm long, that will give us a volume of around 3.1 ltrs excluding the runners.

Behind that you can make out the plate thats going onto the centre plenum, 6 weld els will join plenum to plate.

So there's a ton of fabrication work to do to this plenum alone, and he's also got to sort idle speed control along with a million other headaches I have given him, deepest joy.

He managed to fabricate up the exhaust manifold to turbo pipes, kept them nice and flowing.

Paul fabbed up the Tial external waste gate,this is positioned in such a way that we can easily plumb it into the turbo down pipe, but I've told Paul that its to have a screamer pipe fitted, still at least the choice is there either way now to have a recirculating pipe.

Also made a start on the plenum.

Its a huge amount of work but its great fun!

Here is the plenum bit, obviously in its raw state.

And it mocked up in situ.

Tell me that isn't the scariest f'kin thing you ever saw!!

I promise it will look better when its finished!

Oh yes and here's the throttle body, a 90mm thing off something big!

Overview of where we are now, can you smell the BHP???