so picking up from where we left off last time:

the front coilovers, URAS rack spacers and poly steering rack bushes are now fitted

-

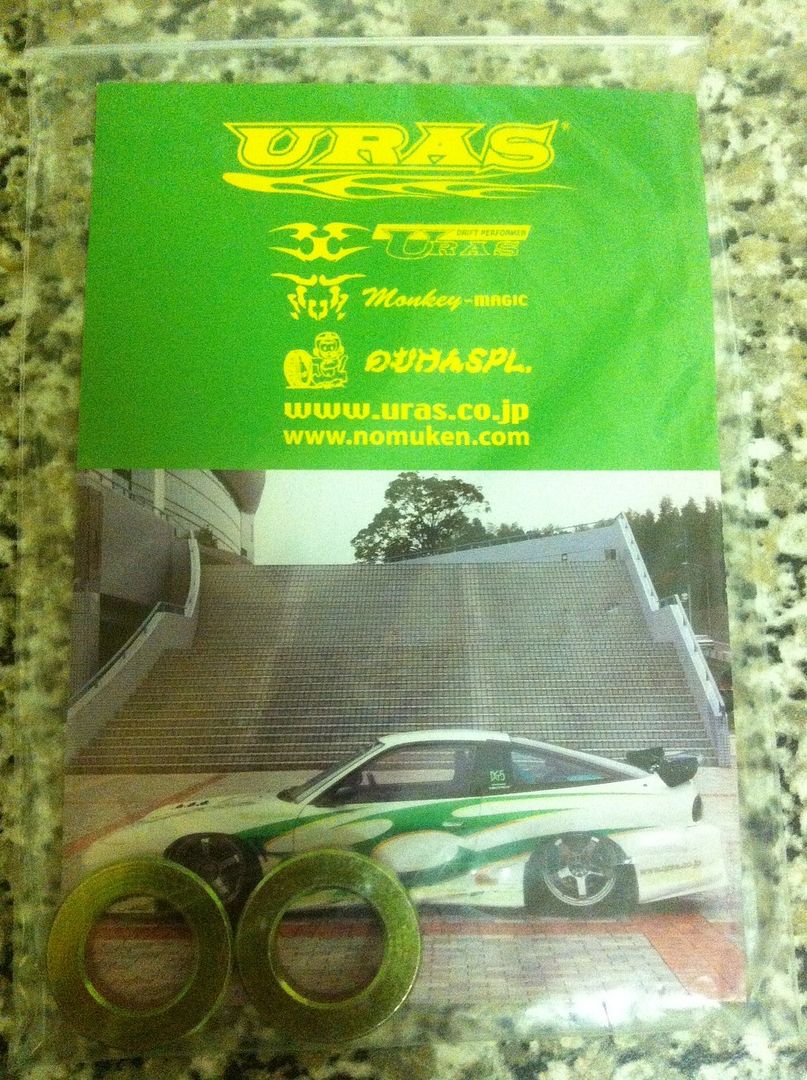

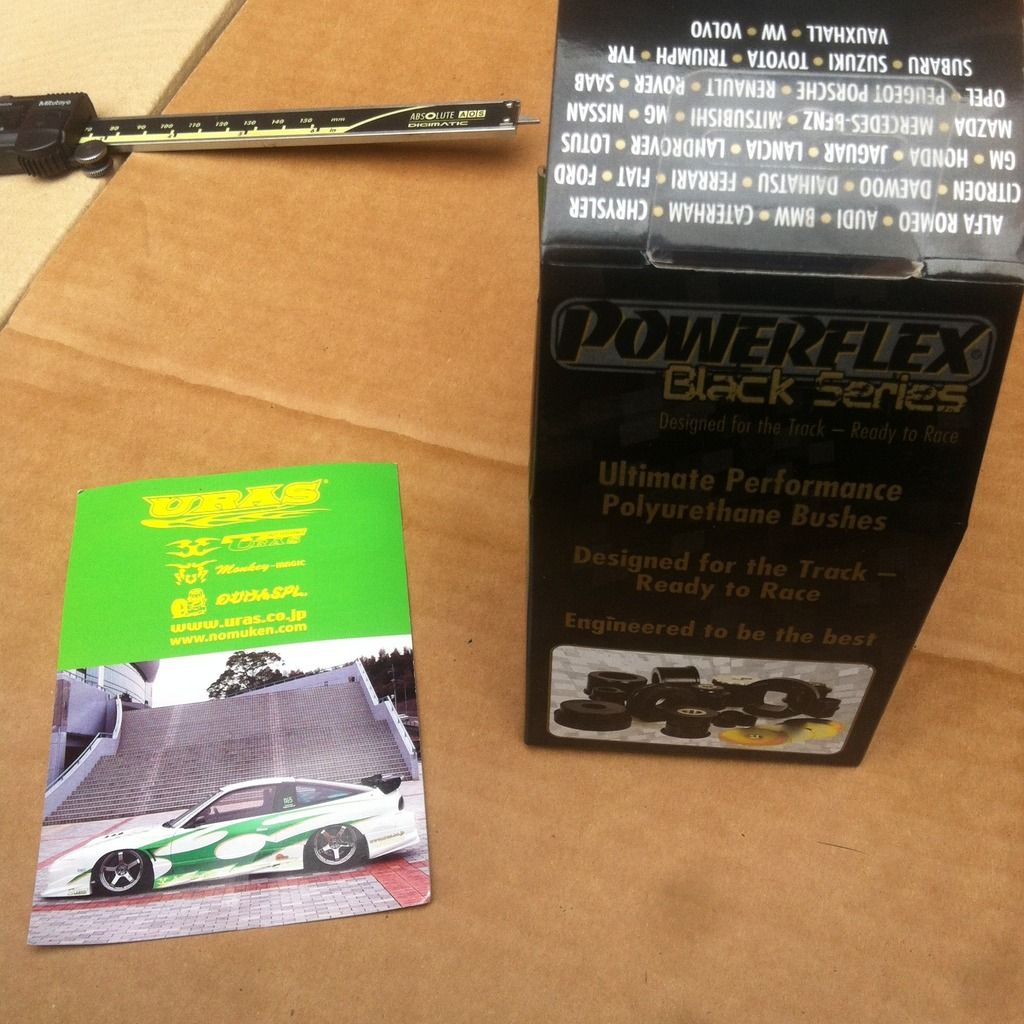

in fact, I don't think I mentioned the rack bushes before?

I kind of thought that while I was under there I might as well replace another part that is as old as the rest of the car and remove the potential for any slop in the steering.

Unfortunately my preferred poly bush brand

(SuperPro) don't do rack mount bushes for the mr2 so I had to buy the powerflex

"black series"

-which at 95 shore are as close as you'll get to a solid mount without actually going fully solid.

yesterday I got started on the turbo install, I already had the x brace, intercooler pipes and air intake pipework off the car so the morning was spent removing undertrays, removing the AC compressor and pulling the CT20b

(for sale now, see for sale section) which took a little more than an hour.

At this point I had the pleasurable job of replacing the hose from hell

(aka no5 coolant bypass hose) which at

£5ish new from toyota is a no brainer to do it now while I can get to it rather than risk it and have it fail in the future.

Then the ATSracing CT to T3 adapter plate was installed using a genuine toyota gasket, brand new genuine toyota locking nuts and Nordlock washers

The turbo was dry fitted, then removed so I could properly clock the housings and nip the bolts up, that was then installed using a genuine nissan rb25

(t3 flange) turbo gasket, new aerolock stainless hardware and nordlock washers

- it's safe to say the turbo and adapter plate are never going to vibrate loose!

the it was a case of installing an oil feed adapter into the block

- namely a M12 to

-4an earls fitting

(the eagle eyed amongst you will notice that this is actually an m12 to 6AN fitting in the picture, once I spotted my mistake I removed it and replaced it with the correct sized one out of my drawer of random AN hose and fittings)

and then a sump flange to 12AN adapter for the oil return

I then made up the oil feed and return lines using Aeroquip FC333 braided hose and goodridge silicone firesleeve to protect them from the heat of the exhaust/turbo

then it was a case of bolting up the wastegate, slipping on the turbo blanket, priming the turbo with oil, spinning the engine over till oil was proven at the oil feed and then starting it up.

.

sounds like a 5 min job when you type it out like that doesn't it?

Unfortunately the bends I bought to make the downpipe aren't tight enough so I've ordered a couple of tight radius bends, when they turn up

(mon/tues?) I'll knock up a downpipe, put the air intake and intercooler pipework back together then it's just a case of tying up loose ends and installing all the rear suspension stuff

(coilovers, hubs, arms) and then it should be time for alignment/MOT/mapping

- eek!

I'm still toying with the idea of spinning the wastegate round and venting the dump pipe/screamer out of the engine lid

- the inner child in me says yes, the

(semi) grownup says no