Hoping the wealth of knowledge on here can help me best formulate a plan going forward.

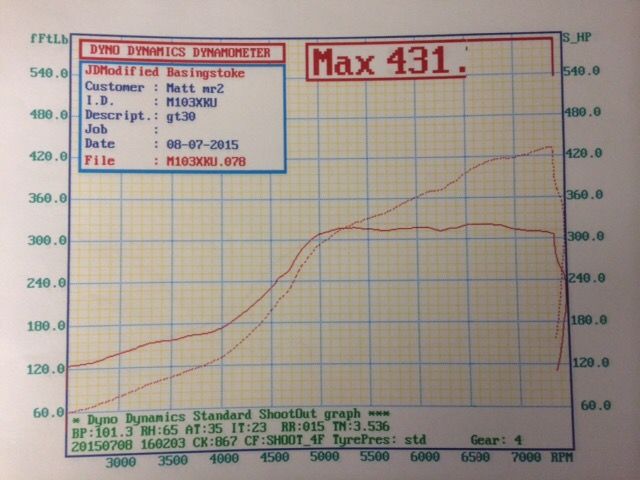

Car is 400hp, forged engine, gt3076r running 1.7 bar as a bit of background.

The following issue didn't occur for the first year to 18 months after finishing this stage of my build, but now has become a reoccurring nightmare.

Problem is that currently on a regular basis after any hard driving

What's people's opinions on best approach?

It's also worth mentioning that the porting and flow on the manifold

My thoughts are get the car running and take to a exhaust fabricator, get a new manifold made, then hit the dyno for a remap.

Ideally individually egt sensors would be sensible but I just don't have the budget anymore since buying a house.

Input and thoughts please